PLANNING

Detailed planning, capacity to adapt and flexibility increase efficiency in different phases of the production process.

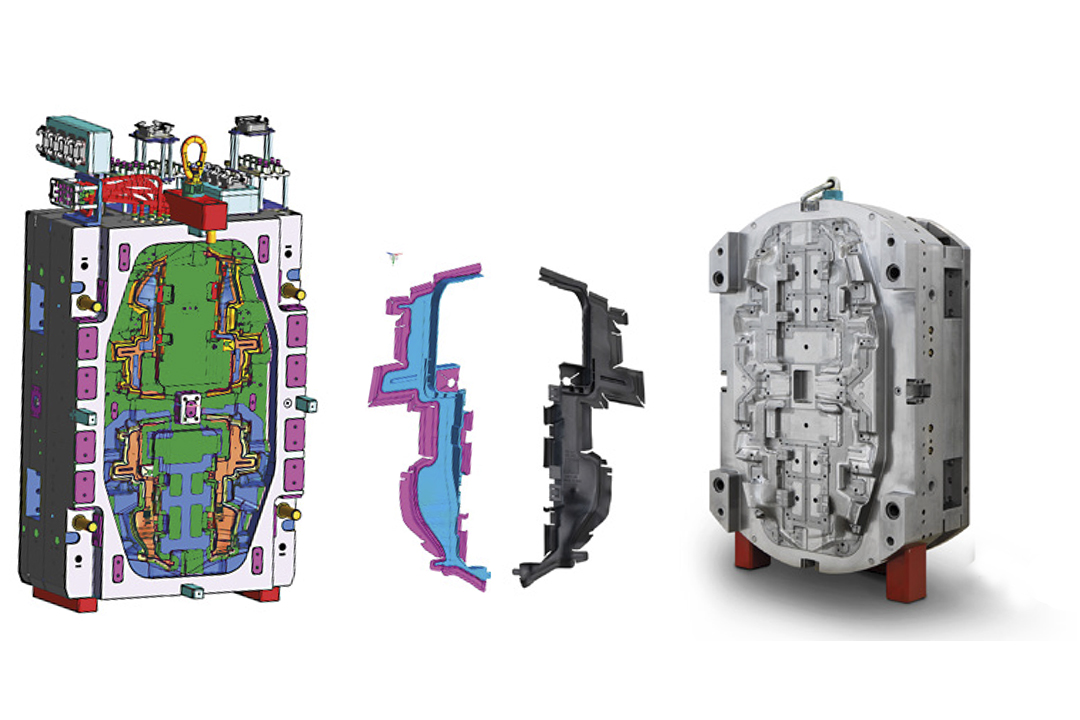

ENGINEERING

Experienced technicians, aided by modern CAD-CAM systems, develop technical solutions to meet the most complex needs.

PRODUCTION

3 rotating shifts, 70 qualified technicians and modern equipment and tools guarantee quick delivery and competitive prices.

MDTFORM operates in one of the specialist sectors and occupies an area of 2500 m2, adding value to its quality and excellent production process. Continuous investment in training and technology leads to its distinction and recognition in the sector.

TRY-OUTS

MDTFORM carries out tests and production at specialized partners to guarantee that they meet clients' needs and surpass their expectations.

QUALITY CONTROL

Client satisfaction is a constant concern at MDTFORM. This means that the whole production process is accompanied and controlled by qualified and experienced technicians with a view to reaching high quality levels. MDTFORM uses a three-dimensional control system to supply an analysis and full dimensional report.

MDTFORM focuses on the quality of the whole process, recognizing it as an essential tool for winning over its clients' trust and preference. The company therefore initiated the Quality Management Certification process by implementing standard ISO 9001:2015.

KNOW-HOW

MDTFORM has the technical and production capacity to develop and manufacture highly complex Sandwich, Bimaterial (2K), Gas-assisted (GID), injection casting molds and others of up to 35 Tons.

TRAINING

MDTFORM has developed partnerships with CENFIM from Marinha Grande, Leiria Polytechnic Institute and others, focusing on training, qualification and development of its technicians with a view to increasing their productivity and performance.